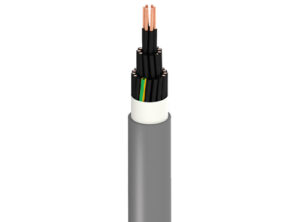

CY/SY/YY Control Cable

CY/SY/YY control cables are types of flexible control cables commonly used in industrial applications for transmitting control signals and power to various electrical equipment and machinery.

Share

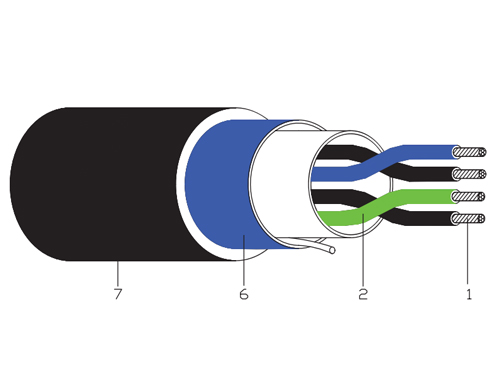

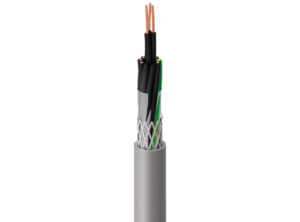

CY Control Cable

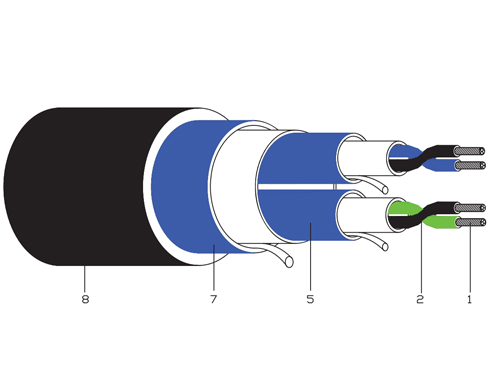

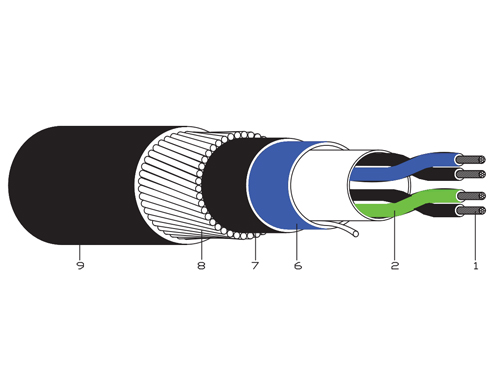

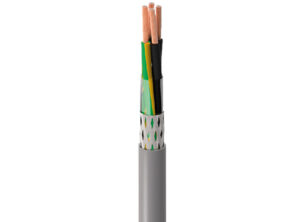

SY Control Cable

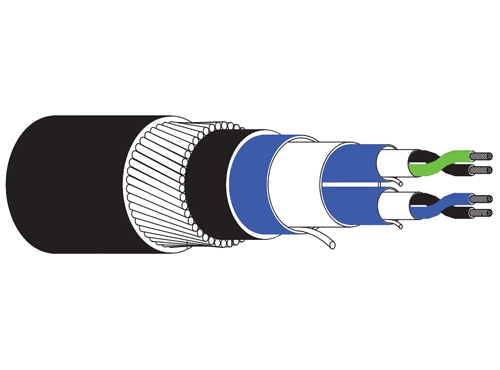

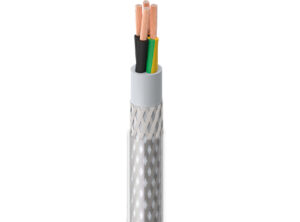

YY Control Cable

Features

CY Control Cable

Construction

- Voltage Rating

300/500V - Conductor

Class 5 flexible plain copper - Insulation

PVC (Polyvinyl Chloride)/LSZH (Low Smoke Zero Halogen) - Separator

PET (Polyester Tape) - Screen

TCWB (Tinned Copper Wire Braid) - Sheath

PVC (Polyvinyl Chloride)/LSZH (Low Smoke Zero Halogen)

Application:

- CY cables are commonly used in industrial automation, machinery control systems, and computerized equipment.

SY Control Cable

Construction

- Voltage Rating

300/500V - Conductor

Class 5 flexible plain copper - Insulation

PVC (Polyvinyl Chloride)/LSZH (Low Smoke Zero Halogen) - Inner Sheath/Bedding

PVC (Polyvinyl Chloride)/LSZH (Low Smoke Zero Halogen) - Armour/Braiding

GSWB (Galvanised Steel Wire Braid) - Sheath

PVC (Polyvinyl Chloride)/LSZH (Low Smoke Zero Halogen)

Application:

- The steel wire braid or helix provides increased resistance against physical damage, making SY cables suitable for applications where the cable may be exposed to mechanical stress, such as in heavy machinery, robotics, and construction equipment.

YY Control Cable

Construction

- Voltage Rating

300/500V - Conductor

Class 5 flexible plain copper - Insulation

PVC (Polyvinyl Chloride)/LSZH (Low Smoke Zero Halogen) - Sheath

PVC (Polyvinyl Chloride)/LSZH (Low Smoke Zero Halogen)

Application:

- YY cables are commonly used in applications where EMI protection is not a critical requirement, such as internal wiring in control panels, office equipment, and low-voltage applications.

Features

All three types of control cables, CY/SY/YY, are typically flexible and available in various conductor sizes and core configurations, including twisted pairs and multi-core versions.

They may have additional features like flame-retardant or oil-resistant properties, depending on the specific application requirements.

Manufacturing Process

Conductor Stranding

Extruded Insulation

Cabling

Armoured

Extruded Outer Sheath

Packing On Drum