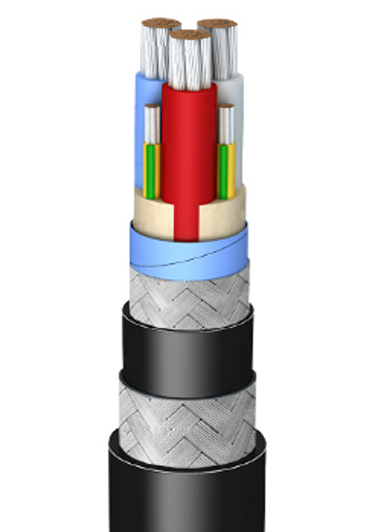

Shipboard Marine Power Cable

Marine cables are used in the marine environment, especially on ships and offshore platforms. These cables are designed to meet the stringent requirements and safety standards required for reliable operation in harsh marine conditions.

Share

Fire Retardant Low Voltage Power Cable

- Conductor:

Stranded tinned annealed copper, IEC 60228 Class 2 - Insulation:

XLPE, IEC 60092-360 - Cabling:

Flame retardant & non-hygroscopic fillers can be used

Suitable tape(s) can be applied on the cabled core - Outer sheath:

Halogen-free flame retardant thermoplastic compound (SHF1)

Halogen-free flame retardant thermoset compound (SHF2) - Flammability:

LSHF Flame retardant

Fire Resistance Low Voltage Power Cable

- Conductor:

Stranded tinned annealed copper, IEC 60228 Class 2 - Fire Resistance:

Mica/glass tape - Insulation:

XLPE, IEC 60092-360 - Cabling:

Flame retardant & non-hygroscopic fillers can be used

Suitable tape(s) can be applied on the cabled core - Outer sheath:

Halogen-free flame retardant thermoplastic compound (SHF1)

Halogen-free flame retardant thermoset compound (SHF2) - Flammability:

LSHF Flame resistant

Flame Retardant Instrumentation Cable (Overall Screen)

- Conductor:

Stranded tinned annealed copper, IEC 60228 Class 2 - Insulation:

XLPE, IEC 60092-360 - Cabling:

Flame retardant & non-hygroscopic fillers can be used

Suitable tape(s) can be applied on the cabled core - Armor:

Tinned copper wire braid - Outer sheath:

Halogen-free flame retardant thermoplastic compound (SHF1)

Halogen-free flame retardant thermoset compound (SHF2) - Flammability:

LSHF Flame resistant

Flame Retardant Instrumentation Cable (Individual Screen)

- Conductor:

Stranded tinned annealed copper, IEC 60228 Class 2 - Insulation:

XLPE, IEC 60092-360 - Individual screen:

AL/PS tape with tinned copper drain wire

Each pair/triad is wrapped with polyester tape to prevent electrical contact with adjacent pairs/triads - Cabling:

Flame retardant & non-hygroscopic fillers can be used

Suitable tape(s) can be applied to the cabled core - Armor:

Tinned copper wire braid - Outer sheath:

Halogen-free flame retardant thermoplastic compound (SHF1)

Halogen-free flame retardant thermoset compound (SHF2) - Flammability:

LSHF Flame resistant

Flame Retardant VFD Cable

- Conductor:

Stranded tinned annealed copper, IEC 60228 Class 5 - Insulation:

XLPE, IEC 60092-360 - Cabling:

Flame retardant & non-hygroscopic fillers may be used

Suitable tape(s) may be applied to the cabled core - Collective screen:

CU/PS tape with tinned copper drain wire - Armor:

Tinned copper wire braid - Outer sheath:

Halogen-free flame retardant thermoplastic compound

Halogen-free flame retardant thermoset compound - Flammability:

LSHF Flame retardant

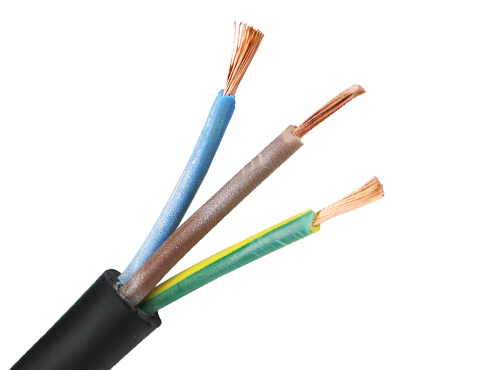

ERP Insulation Marine Flex Cable

- Conductor:

IEC 60228 Class 5

Stranded tinned annealed copper, IEC 60228 Class 5 - Insulation:

EPR, IEC 60092-360 - Laying up:

Cores are laid up together - Sheath:

PCP/PVC - Construction:

Flexible copper conductor

Black, if any - Flammability:

Flame retardant

Manufacturing Process

Conductor Stranding

Extruded Insulation

Cabling

Armoured

Extruded Outer Sheath

Packing On Drum