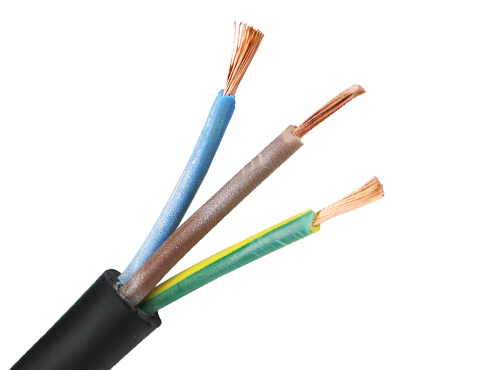

Flexible Copper Wire

Flexible copper wire consists of multiple strands of copper conductors. These copper strands are twisted or braided together to form a flexible and moldable wire.

Share

- Conductor:

Strands Copper Wire - Insulation:

PVC - Sheath:

PVC - Related Voltage:

450/750V - Sheath Color:

Black, Grey, White

Ideal for applications where wires need to pass through tight spaces or where there is movement or vibration, such as in appliances, machinery, automotive wiring and electronic equipment.

Multi-stranded copper wire also provides higher electrical conductivity and reduces the risk of fatigue failure of the solid wire due to repeated bending or vibration.

The main advantage of flexible copper wire is its ability to bend and flex without breaking.

Multi-stranded copper wire also provides higher electrical conductivity and reduces the risk of fatigue failure of solid wire due to repeated bending or vibration.

IEC,ASTM,DIN,BS,etc

Dimensions – conductor cross-section | Construction of individual conductor | External diameter | Insulation thickness | Conductor resistance at 20 °C | Specific. el. resistance of insulation at 70°C | Cu weight | Cable weight | Packing* |

| nominal | min-max. | nominal | max | min. |

| approx. |

|

mm² | n x mm | mm | mm | Ω/km | MΩkm | kg/km | kg/km |

|

1,5 | 30 x 0,25 | 2,8 – 03,4 | 0,7 | 13,3 | 0,0100 | 14,4 | 20 | c.100, c.200 |

2,5 | 50 x 0,25 | 3,4 – 04,1 | 0,8 | 7,98 | 0,0095 | 24,0 | 32 | c.100 |

4 | 56 x 0,30 | 3,9 – 04,8 | 0,8 | 4,95 | 0,0078 | 38,4 | 46 | c.100 |

6 | 84 x 0,30 | 4,4 – 05,3 | 0,8 | 3,30 | 0,0068 | 57,6 | 65 | c.100 |

10 | 80 x 0,40 | 5,7 – 06,8 | 1,0 | 1,91 | 0,0065 | 96,0 | 115 | c.100 |

16 | 128 x 0,40 | 6,7 – 08,1 | 1,0 | 1,21 | 0,0053 | 153,6 | 170 | c.100 |

25 | 200 x 0,40 | 8,4 – 10,2 | 1,2 | 0,780 | 0,0050 | 240 | 260 | CUT |

35 | 280 x 0,40 | 9,7 – 11,7 | 1,2 | 0,554 | 0,0043 | 336 | 360 | CUT |

50 | 400 x 0,40 | 11,5 – 13,9 | 1,4 | 0,386 | 0,0042 | 480 | 515 | CUT |

70 | 356 x 0,50 | 13,2 – 16,0 | 1,4 | 0,272 | 0,0036 | 672 | 710 | CUT |

95 | 485 x 0,50 | 15,1 – 18,2 | 1,6 | 0,206 | 0,0036 | 912 | 940 | CUT |

120 | 614 x 0,50 | 16,7 – 20,2 | 1,6 | 0,161 | 0,0032 | 1152 | 1180 | CUT |

150 | 765 x 0,50 | 18,6 – 22,5 | 1,8 | 0,129 | 0,0032 | 1440 | 1600 | CUT |

185 | 944 x 0,50 | 20,6 – 24,9 | 2,0 | 0,106 | 0,0032 | 1776 | 2100 | CUT |

240 | 1225 x 0,50 | 23,5 – 28,4 | 2,2 | 0,0801 | 0,0031 | 2304 | 3015 | CUT |

Manufacturing Process

Conductor Stranding

Extruded Insulation

Cabling

Armoured

Extruded Outer Sheath

Packing On Drum