H07RN-F/H05RN-F Cable

H07RN-F cables are typically used in industrial settings and H05RN-F cables are typically used in lighter applications.

Share

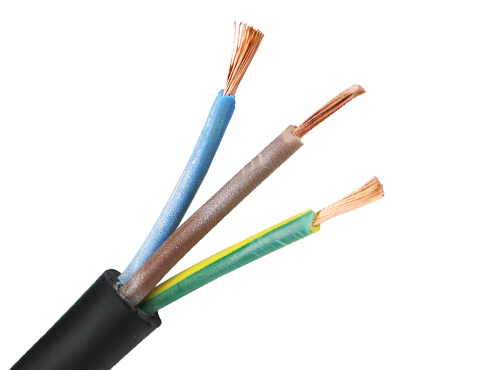

Construction

- Voltage Rating

450/750V - Conductor

Class 5 flexible copper conductor - Insulation

EPR (Ethylene Propylene Rubber) - Sheath

PCP (Polychloroprene)

H07RN-F cables are often used in industrial settings, construction sites, and outdoor applications where durability and resistance to environmental factors are essential.

They are suitable for both indoor and outdoor use, and their flexibility makes them easy to handle and install.

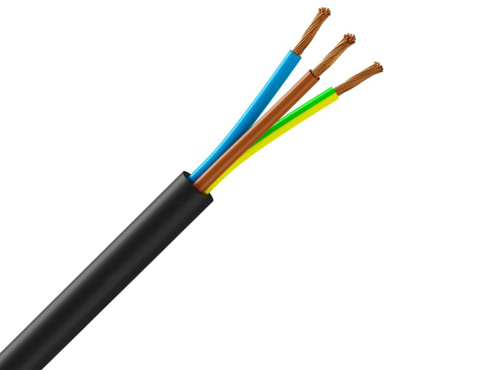

Construction

- Voltage Rating

300/500V - Conductor

Class 5 flexible copper conductor - Insulation

Rubber compound - Sheath

Rubber compound

H05RN-F cables are commonly used for lighter applications such as portable tools, appliances, and household devices.

They are suitable for both indoor and outdoor use, although they may have limitations in terms of their resistance to harsh environmental conditions compared to the heavier-duty H07RN-F cables.

IEC/VED/DIN/ASTM.

Number of cores and mm² per conductor | Outer diameter [mm] | Copper index (kg/km) | Weight (kg/km) |

1 X 1.5 | 5.7 – 6.5 | 14.4 | 59 |

1 X 2.5 | 6.3 – 7.2 | 24 | 72 |

1 X 4.0 | 7.2 – 8.1 | 38.4 | 99 |

1 X 6.0 | 7.9 – 8.8 | 57.6 | 130 |

1 X 10.0 | 9.5 – 10.7 | 96 | 230 |

1 X 16.0 | 10.8 – 12.0 | 153.6 | 320 |

1 X 25.0 | 12.7 – 14.0 | 240 | 450 |

1 X 35.0 | 14.3 – 15.9 | 336 | 605 |

1 X 50.0 | 16.5 – 18.2 | 480 | 825 |

1 X 70.0 | 18.6 – 20.5 | 672 | 1090 |

1 X 95.0 | 20.8 – 22.9 | 912 | 1405 |

1 X 120.0 | 22.8 – 25.1 | 1152 | 1745 |

1 X 150.0 | 25.2 – 27.6 | 1440 | 1887 |

1 X 185.0 | 27.6 – 30.2 | 1776 | 2274 |

1 X 240.0 | 30.6 – 33.5 | 2304 | 2955 |

1 X 300.0 | 33.5 – 36.7 | 2880 | 3479 |

3 G 1.0 | 8.3 – 9.6 | 28.8 | 130 |

2 X 1.5 | 8.5 – 9.9 | 28.8 | 135 |

3 G 1.5 | 9.2 – 10.7 | 43.2 | 165 |

4 G 1.5 | 10.2 – 11.7 | 57.6 | 200 |

5 G 1.5 | 11.2 – 12.8 | 72 | 240 |

7 G 1.5 | 14.7 – 16.5 | 100.8 | 385 |

12 G 1.5 | 17.6 – 19.8 | 172.8 | 516 |

19 G 1.5 | 20.7 – 26.3 | 273.6 | 800 |

24 G 1.5 | 24.3 – 27.0 | 345.6 | 882 |

25 G 1.5 | 25.1 – 25.9 | 360 | 920 |

2 X 2.5 | 10.2 – 11.7 | 48 | 195 |

3 G 2.5 | 10.9 – 12.5 | 72 | 235 |

4 G 2.5 | 12.1 – 13.8 | 96 | 290 |

5 G 2.5 | 13.3 – 15.1 | 120 | 294 |

7 G 2.5 | 17.1 – 19.3 | 168 | 520 |

12 G 2.5 | 20.6 – 23.1 | 288 | 810 |

19 G 2.5 | 25.5 – 31 | 456 | 1200 |

24 G 2.5 | 28.8 – 31.9 | 576 | 1298 |

2 X 4.0 | 11.8 – 13.4 | 76.8 | 270 |

3 G 4.0 | 12.7 – 14.4 | 115.2 | 320 |

4 G 4.0 | 14.0 – 15.9 | 153.6 | 395 |

5 G 4.0 | 15.6 – 17.6 | 192 | 485 |

7 G 4.0 | 20.1 – 22.4 | 268.8 | 681 |

3 G 6.0 | 14.1 – 15.9 | 172.8 | 360 |

4 G 6.0 | 15.7 – 17.7 | 230.4 | 475 |

5 G 6.0 | 17.5 – 19.6 | 288 | 760 |

3 G 10.0 | 19.1 – 21.3 | 288 | 880 |

4 G 10.0 | 20.9 – 23.3 | 384 | 1060 |

5 G 10.0 | 22.9 – 25.6 | 480 | 1300 |

3 G 16.0 | 21.8 – 24.3 | 460.8 | 1090 |

4 G 16.0 | 23.8 – 26.4 | 614.4 | 1345 |

5 G 16.0 | 26.4 – 29.2 | 768 | 1680 |

4 G 25.0 | 28.9 – 32.1 | 960 | 1995 |

5 G 25.0 | 32.0 – 35.4 | 1200 | 2470 |

3 G 35.0 | 29.3 – 32.5 | 1008 | 1910 |

4 G 35.0 | 32.5 – 36.0 | 1344 | 2645 |

5 G 35.0 | 35.7 – 39.5 | 1680 | 2810 |

4 G 50.0 | 37.7 – 41.5 | 1920 | 3635 |

5 G 50.0 | 41.8 – 46.6 | 2400 | 4050 |

4 G 70.0 | 42.7 – 47.1 | 2688 | 4830 |

4 G 95.0 | 48.4 – 53.2 | 3648 | 6320 |

4 G 120.0 | 53.0 – 57.5 | 4608 | 6830 |

4 G 150.0 | 58.0 – 63.6 | 5760 | 8320 |

4 G 185.0 | 64.0 – 69.7 | 7104 | 9800 |

4 G 240.0 | 72.0 – 79.2 | 9216 | 12800 |

Number of cores and mm²per conductor | Outer diameter [mm] | Copper index (kg/km) | Weight (kg/km) |

2 X 0.75 | 5.7 – 6.7 | 14.4 | 55 |

3 G 0.75 | 6.2 – 7.4 | 21.6 | 68 |

4 G 0.75 | 6.8 – 7.9 | 28.8 | 81 |

2 X 1.0 | 6.1 – 7.3 | 19.2 | 63 |

3 G 1.0 | 6.5 – 7.7 | 28.8 | 78 |

Manufacturing Process

Conductor Stranding

Extruded Insulation

Cabling

Armoured

Extruded Outer Sheath

Packing On Drum