Instrumentation Cable

Instrumentation cable is a type of specialized electrical cable used in industrial settings to transmit signals and measurements between instrumentation and control devices.

Share

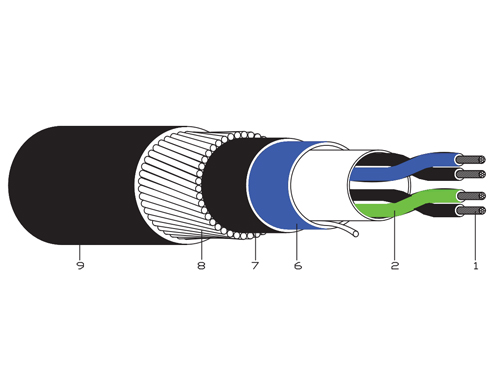

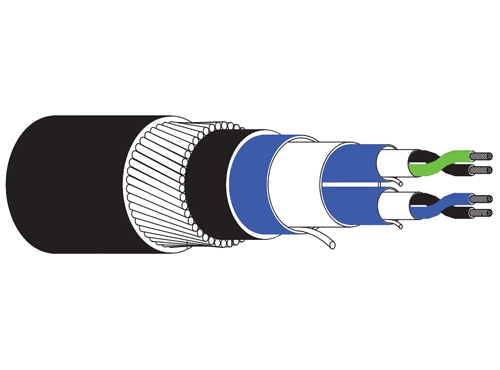

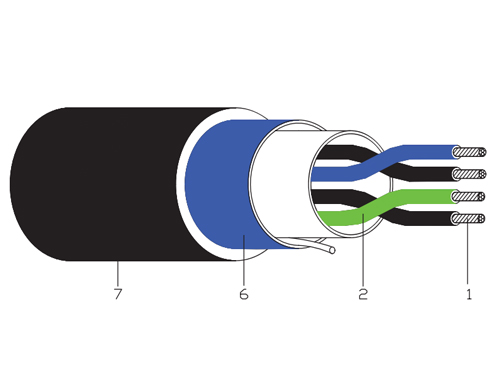

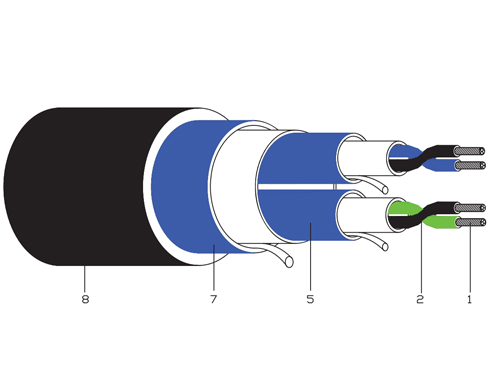

- Voltage:

300/500V - Conductor:

Circular stranded copper - Type:

Single pair or multi-pair - Insulated:

PE or PVC - Pairing:

Two insulated cores shall be uniformly twisted together to form a pair with a maximum lay length of 100mm - Cabling:

Twisted pairs are laid up together if necessary filled with non-hygroscopic material compatible with the insulation. - Overall Screening:

Accumulated pairs screened with aluminum/mylar tape, helically applied with the metallic side down, in electrical contact with a tinned annealed copper drain wire of 0.5mm2 - Sheath:

PVC(Polyvinyl Chloride)

- Voltage:

300/500V - Conductor:

Circular stranded copper - Type:

Multi-pair - Insulated:

PE or PVC - Pairing:

Two insulated cores shall be uniformly twisted together to form a pair with a maximum lay length of 100mm - Individual Screening:

Each pair screen with aluminum/mylar tape, helically applied with the meta side down, in electrical contact with a tinned annealed copper drain wire of 0.5mm2 - Cabling:

Twisted pairs are laid up together if necessary filled with non-hygroscopic material compatible with the insulation. - Overall Screening:

Accumulated pairs screened with aluminum/mylar tape, helically applied with the metallic side down, in electrical contact with a tinned annealed copper drain wire of 0.5mm2 - Sheath:

PVC(Polyvinyl Chloride)

Instrumentation cables are commonly used in industries such as oil and gas, petrochemical, power generation, manufacturing, and process control.

They are employed to connect various instruments and sensors, including temperature sensors, pressure transmitters, flow meters, level detectors, and control valves, to monitoring and control systems.

Huadong’s instrumentation cables are protected against electromagnetic interference (EMI) and radio frequency interference (RFI). Have low capacitance to reduce signal attenuation and distortion. Are heat and chemical resistant and can withstand harsh environmental conditions.

BS 7917, IEC 60331-31.

Size | Number/Wire | Nominal Insulated Thickness | Nominal | Nominal Overall | Approx.Cable Weight |

pair x mm2 | No./mm | mm | mm | mm | Kg /Km |

2x 0.5 | 7 / 0.3 | 0.6 | 0.8 | 7.5 | 75 |

3 x 0.5 | 7 / 0.3 | 0.6 | 1.1 | 10.2 | 119 |

4 x 0.5 | 7 / 0.3 | 0.6 | 1.1 | 11.1 | 129 |

5 x 0.5 | 7 / 0.3 | 0.6 | 1.1 | 12.1 | 156 |

6 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | I3.4 | I80 |

7 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | I3.4 | 196 |

8 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | I4.5 | 220 |

9 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 15.6 | 243 |

10 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 17 | 282 |

11 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 17 | 297 |

12 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 17.5 | 317 |

Size | Number/ Wire | Nominal Insulation Thickness | Nominal Bedding Thickness | Nominal Overall | Approx. Cable Weight |

pair x mm2 | No./mm | mm | mm | mm | /K / /Q |

2 x 0.5 | 7 / 0.3 | 0.6 | 0.9 | 11.1 | 123 |

3 x 0.5 | 7 / 0.3 | 0.6 | 1.1 | 12.2 | 159 |

4 \ 0.5 | 7 / 0.3 | 0.6 | 1.2 | 13.6 | 196 |

5 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | I4.9 | 236 |

6 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 16.2 | 263 |

7 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 16.2 | 288 |

8 \ 0.5 | 7 / 0.3 | 0.6 | 1.2 | 17.6 | 330 |

9 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 19 | 376 |

10 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 20.7 | 409 |

11 x 0.5 | 7 / 0.3 | 0.6 | 1.2 | 20.7 | 434 |

12 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 21.6 | 457 |

13 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 21.7 | 48I |

I4 \ 0.5 | 7 / 0.3 | 0.6 | 1.3 | 21.7 | 506 |

15 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 22.9 | 544 |

16 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 22.9 | 569 |

17 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 24.2 | 597 |

I8 \ 0.5 | 7 / 0.3 | 0.6 | 1.3 | 24.2 | 622 |

19 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 24.2 | 647 |

20 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 25.4 | 688 |

21 x 0.5 | 7 / 0.3 | 0.6 | 1.3 | 25.4 | 712 |

22 x 0.5 | 7 / 0.3 | 0.6 | 1.5 | 27.2 | 783 |

23 x 0.5 | 7 / 0.3 | 0.6 | 1.5 | 27.2 | 809 |

24 \ 0.5 | 7 / 0.3 | 0.6 | 1.5 | 28.9 | 846 |

25 x 0.5 | 7 / 0.3 | 0.6 | 1.5 | 28.9 | 87I |

26 x 0.5 | 7 / 0.3 | 0.6 | 1.5 | 28.9 | 896 |

27 x 0.5 | 7 / 0.3 | 0.6 | 1.5 | 29.6 | 910 |

28 \ 0.5 | 7 / 0.3 | 0.6 | 1.5 | 30.7 | 943 |

29 x 0.5 | 7 / 0.3 | 0.6 | 1.5 | 30.7 | 967 |

30 x 0.5 | 7 / 0.3 | 0.6 | 1.5 | 30.7 | 992 |

31 x 0.5 | 7 / 0.3 | 0.6 | 1.7 | 32.3 | 1062 |

32 x 0.5 | 7 / 0.3 | 0.6 | 1.7 | 32.3 | I086 |

33 x 0.5 | 7 / 0.3 | 0.6 | 1.7 | 32.3 | 1112 |

34 \ 0.5 | 7 / 0.3 | 0.6 | 2 | 34.2 | 1190 |

35 x 0.5 | 7 / 0.3 | 0.6 | 2 | 34.2 | 1215 |

36 x 0.5 | 7 / 0.3 | 0.6 | 2 | 34.2 | 1239 |

Manufacturing Process

Conductor Stranding

Extruded Insulation

Cabling

Armoured

Extruded Outer Sheath

Packing On Drum