7/32” (5.69 mm) Monoconductor

Minimum Sheave Diameter: 14” (36cm)

Cable Stretch Coefficient: 2.2 ft/kft/Klbs (2.5 m/Km/5KN)

Maximum Conductor Voltage: 1,200 VDC

Conductor AWG Rating: 16

Minimum Insulation Resistance: 1,500 MegaΩ/Kft @ 1000VDC (457 Mega Ω/Km @ 1000VDC)

Armor Electrical Resistance: 4.3 Ω/Kft (14.1 Ω/Km)

huadong@hdcablegroup.comMECHANICAL:

Cable Breaking Strength:

Ends Fixed: 5,600 lbs (24.9 KN) Nominal

Maximum Suggested Working Tension: 2,800 lbs (12.5 KN)

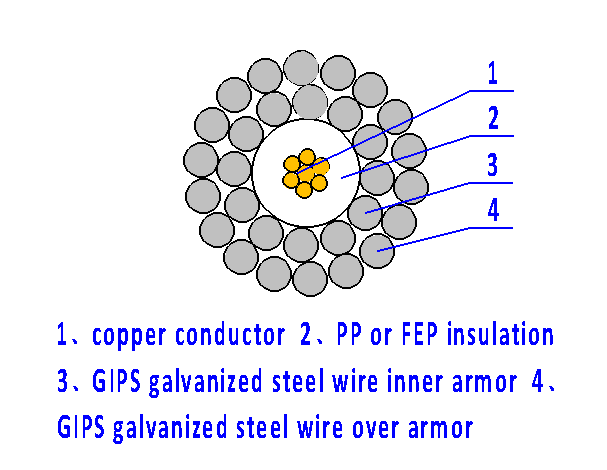

Number and Size of Wires:

Inner Armor 15 x 0.0243” (0.617 mm)

Outer Armor 15 x 0.0358” (0.909 mm)

Average Wire Breaking Strength:

Inner Armor 132 lbs (0.59 KN)

Outer Armor 286 lbs (1.27 KN)

| Core Description | Cable Weight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Temp Rating | Plastic Type | Insulation Thickness | Copper Construction | Res Typical | Cap Typical | O.D. Each | In Air | In H2O | Spec. Gravity | |

| °F | in | in | Ω/Kft | pf/ft | in | lbs/Kft | ||||

| °C | mm | mm | Ω/Km | pf/m | mm | Kg/Km | ||||

| 300* | Poly | 0.0245 | 19x0.0119 | 4.1 | 60 | 0.108 | 91 | 75 | ||

| 149* | 0.622 | 19x0.302 | 13.5 | 197 | 2.743 | 136 | 112 | |||

| 420* | ETFE | 0.0115 | 19x0.0119 | 4.1 | 61 | 0.108 | 92 | 76 | ||

| 216* | 0.292 | 19x0.302 | 13.5 | 200 | 2.743 | 137 | 114 | |||

| 420* | TPX | 0.013 | 19x0.0119 | 41 | 61 | 0.085 | 92 | 76 | ||

| 216* | 0.33 | 19x0.302 | 13.5 | 200 | 2.159 | 137 | 114 | |||

| 500* | ETFE | 0.0115 | 19x0.0119 | 4.1 | 58 | 0.108 | 95 | 78 | ||

| 260* | 0.292 | 19x0.302 | 13.5 | 190 | 2.743 | 140 | 116 | |||

| 500* | FEP | 0.013 | 19x0.0119 | 4.1 | 58 | 0.085 | 95 | 78 | ||

| 260* | 0.33 | 19x0.302 | 13.5 | 190 | 2.159 | 140 | 116 | |||

The armor wires are high tensile, Galvanized Extra Improved Plow Steel (GEIPS), and coated with anti-corrosion compound for protection during shipping and storing. Wires are preformed.

Core assembly – Copper strand consists of a total of nineteen wires. Conductor resistance is measured at 68° F. Voids in the copper strand are filled with a water-blocking agent to reduce water and gas migration.

SUPERSEAL, a special pressure seal agent, is applied between armor layers.

The temperature rating assumes a normal gradient for both temperature and weight.

All values shown are nominal or typical values.

5/16″ (8.18 mm) Monoconductor

Cable Diameter: 0.322″ +0.005″ – 0.002″ (8.18 mm +0.13 mm -0.05mm)

Minimum Sheave Diameter: 18″ (46 cm)

Cable Stretch Coefficient: 1.2 ft/Kft/Klbs (1.35 m/Km/5KN)

Maximum Conductor Voltage: 1,500 VDC

Conductor AWG Rating: 15

Minimum Insulation Resistance: 1,500 MegaΩ/Kft @ 1,000 VDC (457 MegaΩ/Km @ 1000VDC)

Armor Electrical Resistance: 2.1 Ω/Kft (6.9 Ω/Km)

MECHANICAL:

Cable Breaking Strength:

Ends Fixed: 14,750 65.63 KN) Nominal

Maximum Suggested Working Tension: 7,375 (32.7 KN)

Number and Size of Wires:

Inner Armor 12 x 0.0445” (1.130 mm)

Outer Armor 18 x 0.0445” (1.130 mm)

Average Wire Breaking Strength:

Inner Armor 564 (2.5 KN)

Outer Armor 564 (2.5 KN)

| Core Description | Cable Weight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Temp Rating | Plastic Type | Insulation Thickness | Copper Construction | Res Typical | Cap Typical | O.D. Each | In Air | In H2O | Spec. Gravity | |

| °F | in | in | Ω/Kft | pf/ft | in | lbs/Kft | ||||

| °C | mm | mm | Ω/Km | pf/m | mm | Kg/Km | ||||

| 300* | Poly | 0.042 | 19x0.0142 | 2.8 | 48 | 0.155 | 187 | 155 | ||

| 149* | 1.067 | 19x0.361 | 9.2 | 158 | 3.937 | 278 | 230 | |||

| 500* | ETFE | 0.0175 | 19x0.0142 | 2.8 | 46 | 0.155 | 194 | 160 | ||

| 260* | 0.445 | 19x0.361 | 9.2 | 151 | 3.048 | 288 | 238 | |||

| 500* | FEP | 0.0245 | 19x0.0142 | 2.8 | 46 | 0.12 | 194 | 160 | ||

| 260* | 0.622 | 19x0.361 | 9.2 | 151 | 3.048 | 288 | 238 | |||

See attached specification sheet for recommended maximum temperature exposure times.

The armor wires are high tensile, Galvanized Extra Improved Plow Steel (GEIPS), and coated with anti-corrosion compound for protection during shipping and storing. Wires are preformed.

Core assembly – Copper strand consists of a total of nineteen wires. Conductor resistance is measured at 68° F. Voids in the copper strand are filled with a water-blocking agent to reduce water and gas migration.

SUPERSEAL, a special pressure seal agent, is applied between armor layers.

The temperature rating assumes a normal gradient for both temperature and weight. All values shown are nominal or typical values.

9/32” (7.32 mm) Monoconductor

Minimum Sheave Diameter: 16” (41 cm)

Cable Stretch Coefficient: 1.55 ft/Kft/Klbs (1.74 m/Km/5KN)

Maximum Conductor Voltage: 1,500 VDC

Conductor AWG Rating: 15

Minimum Insulation Resistance: 1,500 MegaΩ/Kft @ 1000VDC (457 MegaΩ/Km @ 1000VDC)

Armor Electrical Resistance: 2.8 Ω/Kft (9.2 Ω/Km)

MECHANICAL:

Cable Breaking Strength:

Ends Fixed: 10,200 lbs (45.4 KN) Nominal

Maximum Suggested Working Tension: 5,100 lbs (22.7 KN)

Number and Size of Wires:

Inner Armor 12 x 0.0400” (1.016 mm)

Outer Armor 18 x 0.0400” (1.016 mm)

Average Wire Breaking Strength:

Inner Armor 393 lbs (1.75 KN)

Outer Armor 393 lbs (1.75 KN)

| Core Description | Cable Weight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Temp Rating | Plastic Type | Insulation Thickness | Copper Construction | Res Typical | Cap Typical | O.D. Each | In Air | In H2O | Spec. Gravity | |

| °F | in | in | Ω/Kft | pf/ft | in | lbs/Kft | ||||

| °C | mm | mm | Ω/Km | pf/m | mm | Kg/Km | ||||

| 500* | ETFE | 0.019 | 19x0.0142 | 2.8 | 50 | 0.136 | 157 | 130 | ||

| 260* | 0.483 | 19x0.361 | 9.2 | 180 | 3.454 | 234 | 234 | |||

| 500* | FEP | 0.0135 | 19x0.0142 | 2.8 | 50 | 0.098 | 157 | 130 | ||

| 260* | 0.343 | 19x0.361 | 9.2 | 180 | 2.489 | 234 | 193 | |||

| 300* | Poly | 0.0325 | 19x0.0142 | 2.8 | 56 | 0.136 | 152 | 126 | ||

| 149* | 0.826 | 19x0.361 | 9.2 | 184 | 3.454 | 226 | 187 | |||

| 420* | Camtane | 0.0135 | 19x0.0142 | 2.8 | 55 | 0.098 | 155 | 128 | ||

| 216* | 0.343 | 19x0.361 | 9.2 | 184 | 2.489 | 230 | 190 | |||

| 420* | ETFE | 0.019 | 19x0.0142 | 2.8 | 55 | 0.136 | 155 | 128 | ||

| 216* | 0.483 | 19x0.361 | 9.2 | 184 | 3.454 | 230 | 190 | |||