Application of Servo Motor Cable

Suitable for servo systems such as drag chain control systems, high-price warehouse storage, and extraction equipment, processing equipment/machine tools, rapid conveying systems, dust-free rooms, semiconductor equipment, outdoor lifting, and low-temperature applications. The combination of the power line and the signal core can meet the requirement of power supply and signal transmission.

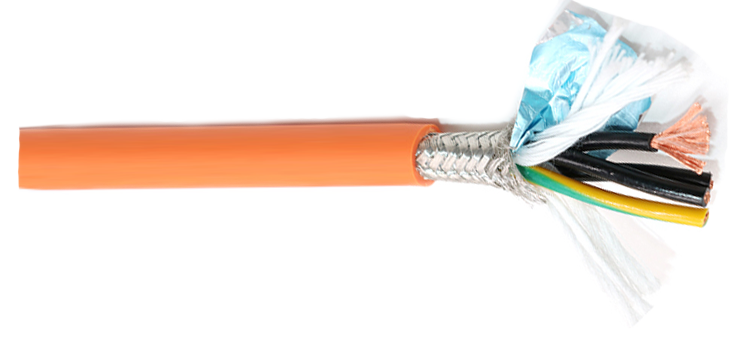

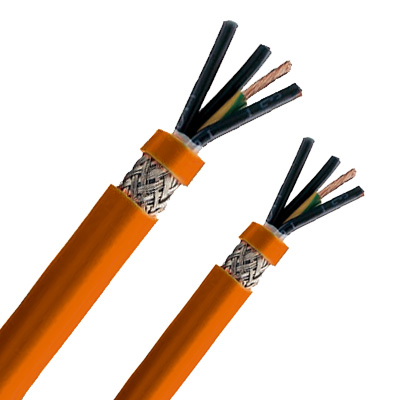

Construction

Rated Voltage: U0~U<0.5mm2 300/300V

U0~U>0.5mm2 300/500V

Conductor: fine bare copper multi stranded wire with high bending strength

Insulation: low capacitance TPE mixture with high mechanical properties

Sub shielding: high bending strength of tin plated copper wire braiding shield, weaving density:85%

Total shielding layer: high bending strength tin plated copper wire braided shielding, braiding density:85%

Inner sheath: pur mixture, suitable for drag chain

Outer sheath: pur mixture, abrasion resistant and tensile, suitable for drag chain.

Operating remperature range:

C mobile installation: -20C ~ +80C

Fixed installation: -40C to +80C

Minimum bedding radius: fixed installation: 4xd

Mobile installation: 7.5xd

The Servo Cable Technical Date

| Item No. | No. of conductor incl. ground | Inch | mm | cable weight ≈lbs/mft |

| 16AWG • 1.50 mm | 4 | 0.335 | 8.5 | 78 |

| 14AWG • 2.50 mm2 | 4 | 0.366 | 9.3 | 107 |

| 12AWG • 4.00 mm2 | 4 | 0.469 | 11.9 | 176 |

| 10AWG 6.00 mm2 | 4 | 0.535 | 13.6 | 238 |

| 8AWG • 10.00 mm2 | 4 | 0.843 | 21.4 | 415 |

| 6AWG • 16.00 mm2 | 4 | 0.874 | 22.2 | 617 |

| 4 AWG • 25.00 mm2 | 4 | 1.024 | 26 | 886 |

| 2AWG • 35.00 mm2 | 4 | 1.154 | 29.3 | 1183 |

| 1AWG • 50.00 mm2 | 4 | 1.205 | 30.6 | 1633 |