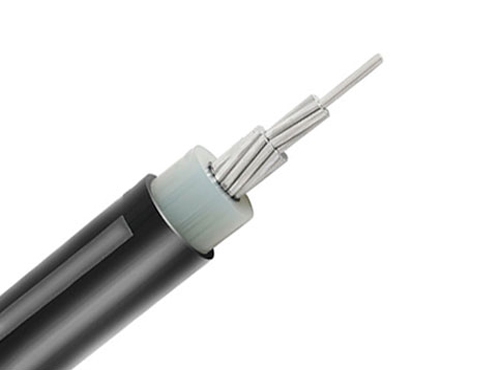

Service Entrance Cable

Service entrance cable is specifically designed to handle the high voltage and current levels required for supplying electricity to the premises.

Share

Voltage:

0.6/1kV

Conductor:

Copper, AAC, AAAC, Copper clad aluminum

Insulated:

XLPE/PVC/PE

Out Sheath:

PE/PVC

Service entrance cables are typically installed underground or overhead, connecting the electric meter on the exterior of the building to the main electrical panel or load center inside.

They serve as the primary connection point between the utility’s power lines and the electrical system of the building.

It is constructed with multiple conductors, including phase conductors (usually black, red, or blue insulated wires), a neutral conductor (typically white or gray insulated wire), and sometimes a bare copper or green-insulated grounding conductor.

The conductors are typically made of copper or aluminum, with copper being more common due to its superior conductivity.

IECA Standard, NFC Standard.

Conductor | Stranding | Nominal O.D. (Mils) | Allowable Ampacities | Approximat e Net Weight Per 1000′ (Lbs) | Standard Package | ||||

Size/Const. AWG or kcmil | Phase Conductor & Neutral | Equipment Ground Conductor |

| 60°C | 75°C | 90°C | Dwelling |

|

|

8-8-8 | 7 | — | 586 | 40 | 50 | 55 | — | 231 | B |

6-6-6 | 7 | — | 669 | 55 | 65 | 75 | — | 338 | B |

4-4-4 | 7 | — | 764 | 70 | 85 | 95 | 100 | 498 | B |

3-3-3 | 7 | — | 829 | 85 | 100 | 110 | 110 | 611 | B |

2-2-2 | 7 | — | 896 | 95 | 115 | 130 | 125 | 752 | B |

1-1-1 | 19 | — | 1021 | 110 | 130 | 150 | 150 | 948 | C |

1/0-1/0-1/0 | 19 | — | 1114 | 125 | 150 | 170 | 175 | 1169 | C |

2/0-2/0-2/0 | 19 | — | 1209 | 145 | 175 | 195 | 200 | 1444 | C |

3/0-3/0-3/0 | 19 | — | 1317 | 165 | 200 | 225 | 225 | 1792 | C |

4/0-4/0-4/0 | 19 | — | 1438 | 195 | 230 | 260 | 250 | 2226 | C |

Conductor | Stranding | Nominal O.D. (Mils) | Allowable Ampacities | Approximat e Net Weight Per 1000′ (Lbs) | Standard Package | ||||

Size/Const. AWG or kcmil | Phase Conductor & Neutral | Equipment Ground Conductor |

| 60°C | 75°C | 90°C | Dwelling |

|

|

8-8-8-8 | 7 | 7 | 645 | 40 | 50 | 55 | — | 286 | B |

6-6-6-6 | 7 | 7 | 738 | 55 | 65 | 75 | — | 424 | B |

4-4-4-6 | 7 | 7 | 844 | 70 | 85 | 95 | 100 | 585 | B |

3-3-3-5 | 7 | 7 | 910 | 85 | 100 | 110 | 110 | 719 | B |

2-2-2-4 | 7 | 7 | 984 | 95 | 115 | 130 | 125 | 887 | B |

1-1-1-3 | 19 | 7 | 1132 | 110 | 130 | 150 | 150 | 1117 | C |

1/0-1/0-1/0-2 | 19 | 19 | 1235 | 125 | 150 | 170 | 175 | 1382 | C |

2/0-2/0-2/0-1 | 19 | 19 | 1342 | 145 | 175 | 195 | 200 | 1713 | C |

3/0-3/0-3/0-1/0 | 19 | 19 | 1462 | 165 | 200 | 225 | 225 | 2129 | C |

4/0-4/0-4/0-2/0 | 19 | 19 | 1598 | 195 | 230 | 260 | 250 | 2650 | C |

Conductor | Stranding | Nominal O.D. (Mils) | Allowable Ampacities | Approximat e Net Weight Per 1000′ (Lbs) | Standard Package | ||||

Size/Const. AWG or kcmil | Phase Conductor & Neutral | Equipment Ground Conductor |

| 60°C | 75°C | 90°C | Dwelling |

|

|

10-10-10 | 1 | 12 | 428 X 283 | 30 | 30 | 30 | — | 127 | ABC |

8-8-8 | 7 | 8 | 587 X 380 | 40 | 50 | 60 | — | 211 | ABC |

6-6-6 | 7 | 12 | 659 X 416 | 55 | 65 | 75 | — | 308 | BCE |

4-4-4 | 7 | 12 | 815 X 506 | 70 | 85 | 95 | 100 | 471 | BCE |

3-3-3 | 7 | 12 | 883 X 548 | 85 | 100 | 110 | 110 | 583 | B |

2-2-2 | 7 | 15 | 994 X 578 | 95 | 115 | 130 | 125 | 718 | BD |

1-1-1 | 19 | 14 | 1093 X 664 | 110 | 130 | 150 | 150 | 904 | B |

1/0-1/0-1/0 | 19 | 19 | 1179 X 707 | 125 | 150 | 170 | 175 | 1123 | BC |

2/0-2/0-2/0 | 19 | 18 | 1283 X 767 | 145 | 175 | 195 | 200 | 1379 | BC |

3/0-3/0-3/0 | 19 | 14 | 1429 X 862 | 165 | 200 | 225 | 225 | 1712 | BC |

4/0-4/0-4/0 | 19 | 18 | 1541 X 918 | 195 | 230 | 260 | 250 | 2146 | BC |

Conductor | Stranding | Nominal O.D. (Mils) | Allowable Ampacities | Approximat e Net Weight Per 1000′ (Lbs) | Standard Package | ||||

Size/Const. AWG or kcmil | Phase Conductor & Neutral | Equipment Ground Conductor |

| 60°C | 75°C | 90°C | Dwelling |

|

|

6-6-8 | 7 | 8 | 659 X 416 | 55 | 65 | 75 | — | 281 | BC |

4-4-6 | 7 | 12 | 790 X 481 | 70 | 85 | 95 | 100 | 420 | BC |

3-3-5 | 7 | 12 | 843 X 508 | 85 | 100 | 110 | 110 | 515 | BC |

2-2-4 | 7 | 12 | 929 X 563 | 95 | 115 | 130 | 125 | 639 | BC |

Manufacturing Process

Conductor Stranding

Extruded Insulation

Cabling

Armoured

Extruded Outer Sheath

Packing On Drum