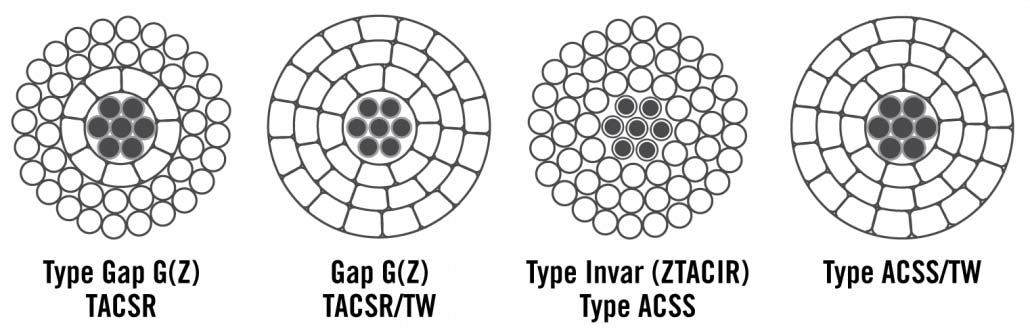

TACSR Conductor Construction:

1. Inner Core wire: The center wire or wires are of galvanized steel and the outer layer or layers of thermal-resistant aluminum-alloy.

2. Inner Core wire : TACSR Conductors are very similar in construction to a conventional ACSR conductor but the EC Grade Aluminum wires are replaced with Hard Drawn Aluminum wires of Heat Resistant Aluminum Alloy (generally known as TAL ).

Standard: IEC,ASTM etc.other internation standard.

TACSR Conductor Application:

TACSR-Thermal Resistance Aluminum alloy Conductor Steel Reinforced Best suited for enhancing the existing line capacity where additional power corridors are not feasible.it could withstand high tensile load to be used mainly for overhead transmission lines, overhead distribution wire.

Features:

1.Stable at elevated temperatures,TACSR can be safely operated continuously above 150oC enabling to pump.more current through the conductor.

2.High Current carrying capacity.

3.Good mechanical properties.

Ability of the Zirconium doped aluminum alloy to maintain its electrical and mechanical properties at elevated temperatures makes these conductors a very cost effective solution in refurbishing the existing lines with enhanced capacity.

TACSR (Thermal Resistance Aluminium Alloy Conductor Steel Reinforced)

| Nominal Cross | No/Dia of Wire | Cross Sectional Area | Approximately | |||

| Sectional Area | TAL Wire | AS Wire | TAL Wire | Total | Overall Dia. | Net Weight |

| No./mm | mm2 | mm | kg/km | |||

| 58 | 6/3.5 | 1/3.5 | 57.73 | 67.35 | 10.5 | 234 |

| 80 | 6/4.2 | 1/4.2 | 83.13 | 96.98 | 12.6 | 336 |

| 80 | 15/2.6 | 4/2.6 | 79.64 | 100.88 | 13 | 386 |

| 95 | 6/4.5 | 1/4.5 | 95.43 | 111.33 | 13.5 | 386 |

| 100 | 15/2.9 | 4/2.9 | 99.08 | 125.5 | 14.5 | 480 |

| 120 | 15/3.2 | 4/3.2 | 120.64 | 152.81 | 16 | 585 |

| 120 | 30/2.3 | 7/2.3 | 124.64 | 153.72 | 16.1 | 574 |

| 160 | 30/2.6 | 7/2.6 | 159.28 | 196.45 | 18.2 | 734 |

| 200 | 30/2.9 | 7/2.9 | 198.16 | 244.4 | 20.3 | 912 |

| 240 | 30/3.2 | 7/3.2 | 241.27 | 297.57 | 22.4 | 1111 |

| 330 | 26/4.0 | 7/3.1 | 326.73 | 379.56 | 25.3 | 1320 |

| 410 | 26/4.5 | 7/3.5 | 413.51 | 480.86 | 28.5 | 1674 |

| 520 | 54/3.5 | 7/3.5 | 519.54 | 586.89 | 31.5 | 1969 |

| 610 | 54/3.8 | 7/3.8 | 612.42 | 691.81 | 34.2 | 2321 |

| 680 | 54/4.0 | 7/4.0 | 678.58 | 766.54 | 36 | 2572 |

| 680 | 45/4.4 | 7/2.9 | 684.24 | 730.48 | 35.1 | 2260 |

Continuous operating temperature of conductor = 80℃, Air temperature = 35℃, wind velocity = 0.6 m/sec